One of the best nitrogen generator for IPG lightWELD system

Designed for plug-and-play use without specialist installation or commissioning, it is fitted with a pre-filter, pressure gauge and flow meter to ensure a stable supply of nitrogen flow and pressure.

- 3m³ Nitrogen generator can support 3-4 sets of IPG lightWELD at the same time

- High purity nitrogen gas generated on site with stable and reliable gas flow

- Stable 99.97-99.99% purity of nitrogen prepared by recyclable high-grade molecular sieves

- Perfectly matched to the nitrogen flow requirements of the IPG lightWELD laser welding system

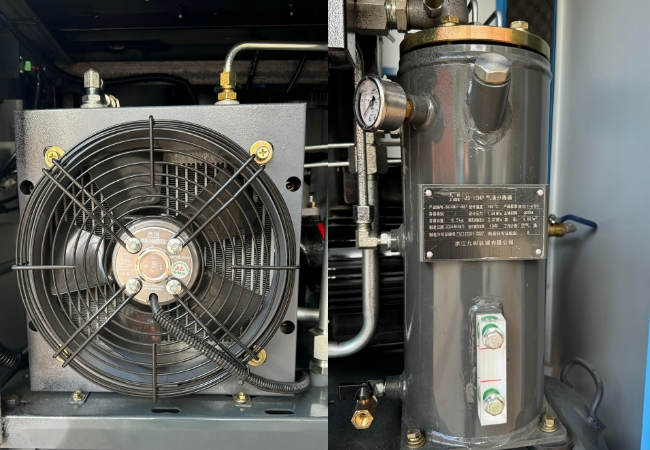

Oil and water separator of the nitrogen generator

Air compressor in the process of mechanical work may produce lubricant leakage and atomization into the air to be compressed. Therefore, the compressed air from the general air compressor can not be directly connected to the laser cutting or welding pipeline system. The oil will pollute the pipeline wall and laser focusing lens, etc. and cause your IPG lightWELD welding torches damages.

The MOZLASER nitrogen generator is equipped with an oil/water separator to ensure that the output nitrogen’s cleanliness grading be 50 PPM.

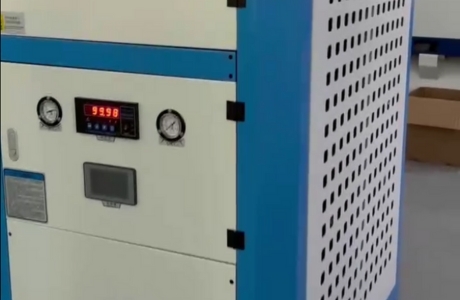

Air cooling dryer keep the nitrogen output strictly cleaning

As we all know, the gas required by IPG lightWELD laser welding systems are very strict, the cleanliness of nitrogen gas must reach 50PPM or less. Both the oil and water content must be below this value.

Therefore, MOZLASER has installed a cooling dryer in every nitrogen generator to ensure that the water content of the output nitrogen gas is less than 50PPM, which effectively protects your laser focus lenses and laser welding torches.

Nitrogen generator is best way to save your welding costs

Bottled nitrogen gas and liquid nitrogen costs have become the biggest costs in the IPG lightWELD laser welding applications, as nitrogen is a daily consumable in both laser welding and other welding methods.

We recommend you to use a nitrogen generator because it saves you costs in several ways: First, no need to purchase nitrogen gas and allows you to consume only low-cost electricity. Second, there are no additional costs such as order processing, refills and delivery charges. Third, the nitrogen generator for IPG lightWELD just needs limited maintenance costs.

- Technical parameters of the 3m³ nitrogen generator

| Nitrogen Generator for Laser Welding Machine | |

| Model | MZ-N2-3m³ |

| Power Supply ( V/PH/HZ) | 220/1/50 or 220/3/60 |

| Technical parameters of air compressor | |

| atmospheric pressure(kg/cm2A) | 1.033 |

| Maximum ambient temperature (℃) | ≤45 |

| Noise(dBA) | 65±2 |

| Maximum working pressure(MPa) | 0.8 |

| Exhaust volume (m3/min) | 0.6 |

| Transmission mode | Direct drive |

| Cooling mode | Air cooling |

| Motor power(kW) | 4.5 |

| Technical parameters of cooling dryer | |

| Air handling capacity(M³/min) | 1.5 |

| Maximum inlet pressure(Mpa) | 1.6 |

| Inlet temperature(℃) | ≤45 |

| Rated maximum ambient(℃) | 40 |

| Dew point temperature(℃) | 6℃ |

| Refrigerant | R22 |

| Cooling mode | Air cooling |

| Technical parameters of the nitrogen generation | |

| Nitrogen flow rate | 3 cubic meter/hour |

| Purity of nitrogen output | 99.97%-99.99% |

| Whole generator size(air compressor included) | 120×85×168CM(L×W×H) |

| Whole generator weight(air compressor included) | 368KG |

| Total power(air compressor included) | 5KW |

About the life span of molecular sieve of PSA nitrogen generator and the daily maintenance cost of nitrogen generator

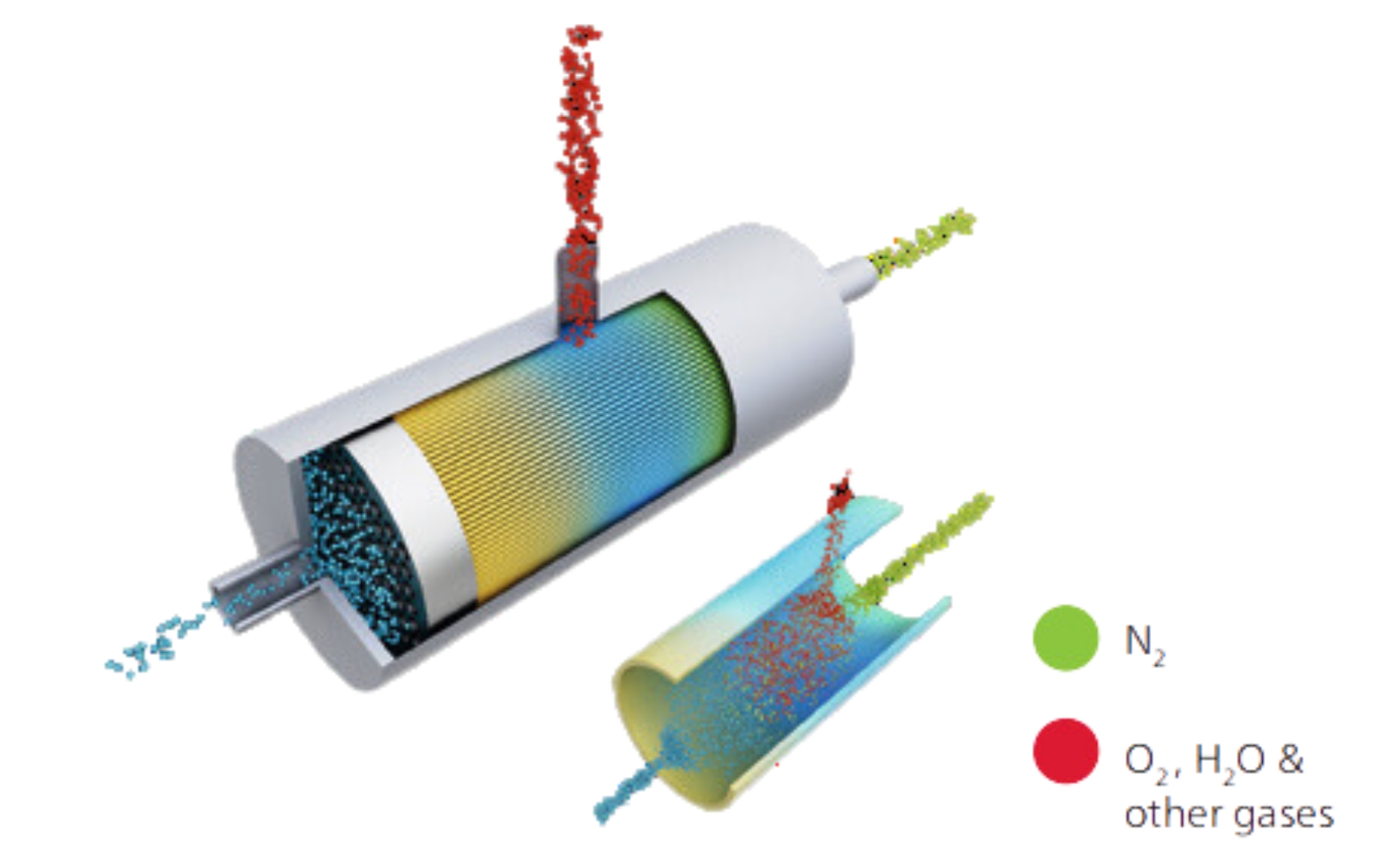

The core component of PSA nitrogen generator carbon molecular sieve is mainly used to adsorb the nitrogen in the air under a certain pressure. Because of the difference in the diameter of oxygen and nitrogen molecules, oxygen will be preferentially adsorbed, while nitrogen will be retained becoming high purity of nitrogen gas flow. When the pressure of the molecular sieve decreases, the oxygen and other impurities will be detached from the molecular sieve, and the molecular sieve is regenerated. The molecular sieve of MOZLASER nitrogen generator is designed with two towers, one for adsorption and the other for deoxygenation and regeneration.

And this is the process of physical adsorption, theoretically the number of cycles of carbon molecular sieve is unlimited. But the actual use of the front-end compressed air needs to be considered whether the compressed air can be free of oil and water, and do a good job of filtration. The actual service life can reach about 5 years as the market feedback. Molecular sieve part is no need daily maintenance and required . only the air compressor maintenance, including the change of lubricating oil, replacement of air filter oil filter and other filtration components. Specific air compressor maintenance please check our air compressor details page which contains the maintenance details and accessories needs.

We provide 220V 50hz,single phase for most of the countries from Asia or EU

And another version with 220V 60HZ,3 phases for north America countries.

If your power supply is different with standard one,please contact us for customzation.

First of all,we will do the plywood crates pacakge for the nitrogen generator in our factory firstly.

Second,about the shipment, in the most the countries of the world we have door to door shipment service.

But if you have your own delivery chain,we also can be linked to your shipping forwarder.